Workshops

Lighting in workshops should follow the guidelines for similar spaces in industry. It is important that shadows and areas of high contrast be avoided, which can be achieved by using lower-power luminaires with good vertical illumination characteristics mounted closer together, rather than fewer, high output luminaires spaced more widely.

Workshop activities may involve close work on machines, so additional task lighting will be required.

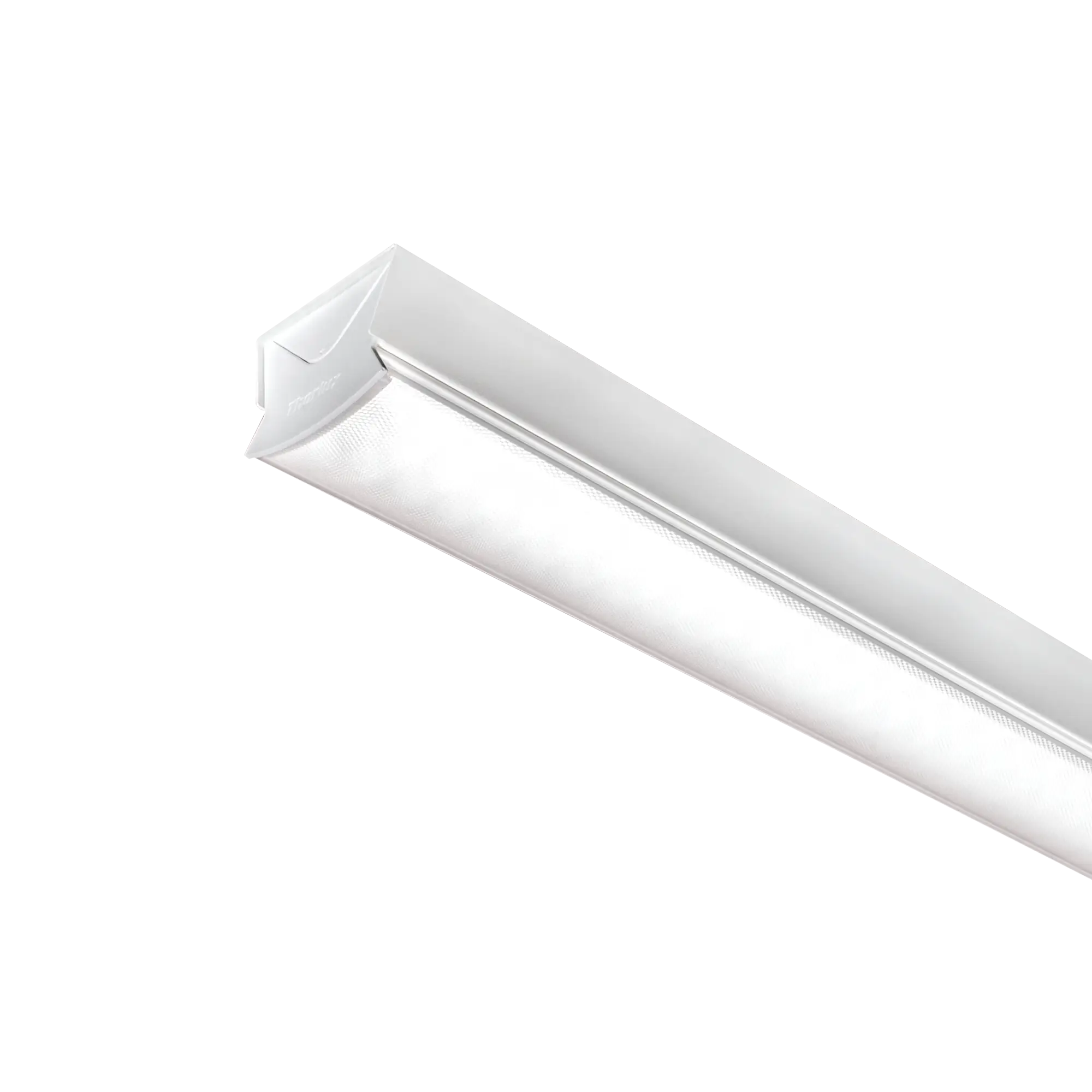

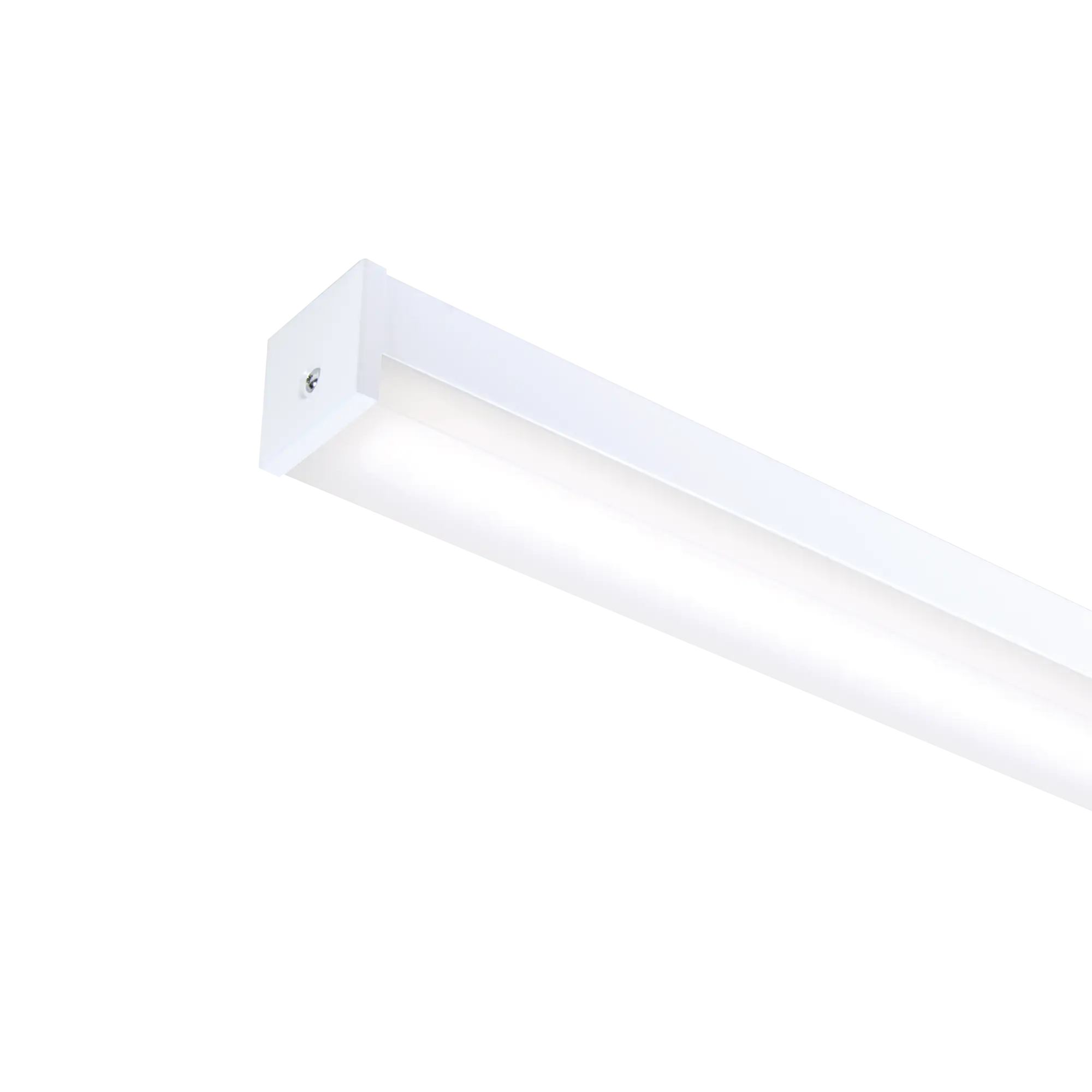

Choice of Luminaire

Sealed luminaires are often needed to exclude dust, so A-Line and Thoroproof are ideal.

If corrosive oil fumes are likely to be present in the atmosphere, the A-Line with an acrylic cover should be used because acrylic is more corrosion resistant than polycarbonate.

Illumination Levels

Extract from CIBSE: SLL Lighting Guide 5 - Lighting for Education 2011

| Application | Maintained Horizontal Illuminance (lux) | UGRL | U0 | Ra |

|---|---|---|---|---|

| Practical Teaching Spaces | 500 | 19 | 0.6 | 80 |

| Note: In some applications, Industry lighting standards appropriate for the task should be followed. See CIBSE: SLL Lighting Guide 1 - Industrial Environment 2018 | ||||

SmartScan Lighting Management

Manual control is sometimes needed in order to dim the luminaires for demonstration purposes, so a SmartScan Scene Touch Plate may be configured with a demonstration scene that is selected at the touch of a button.

Find out more

Find out more

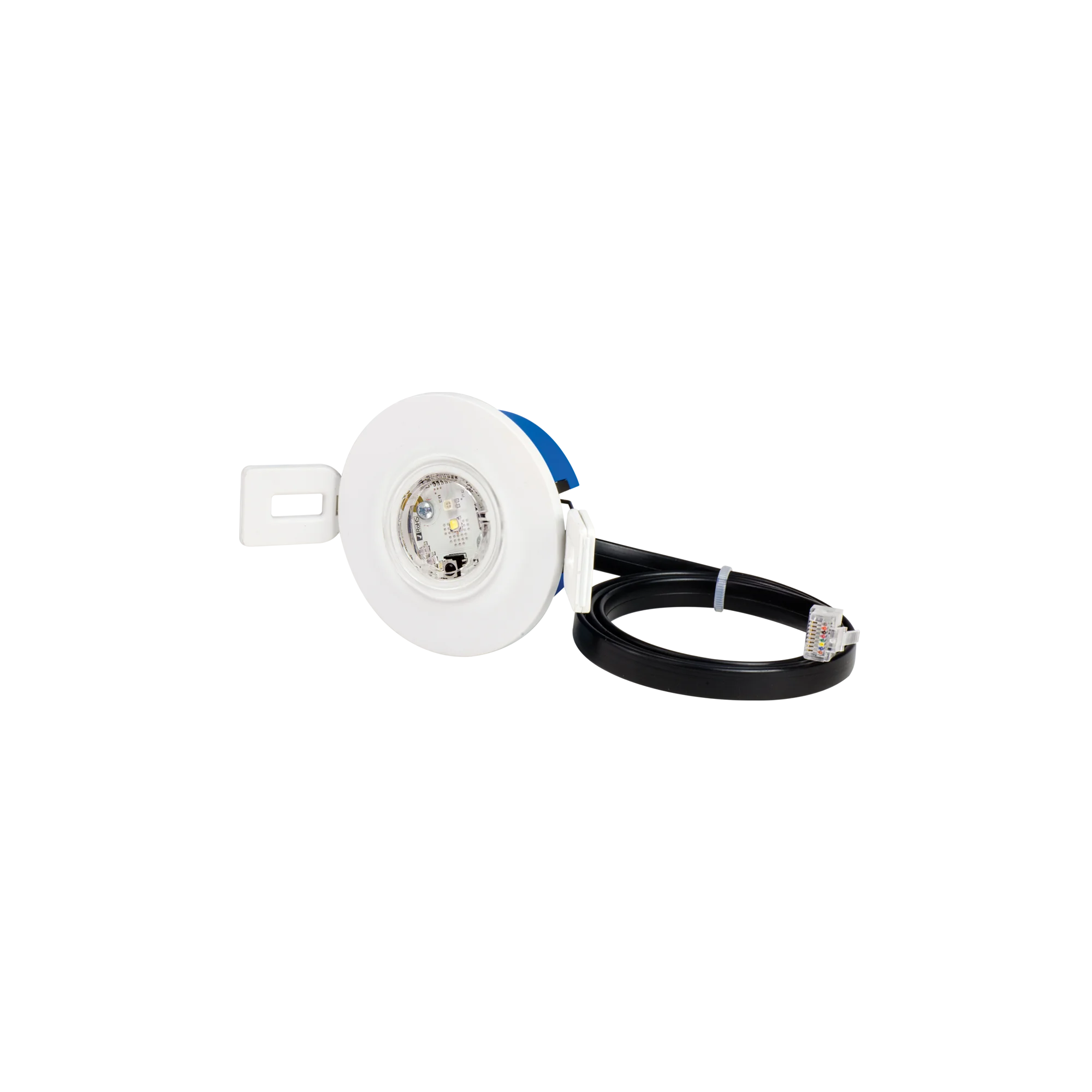

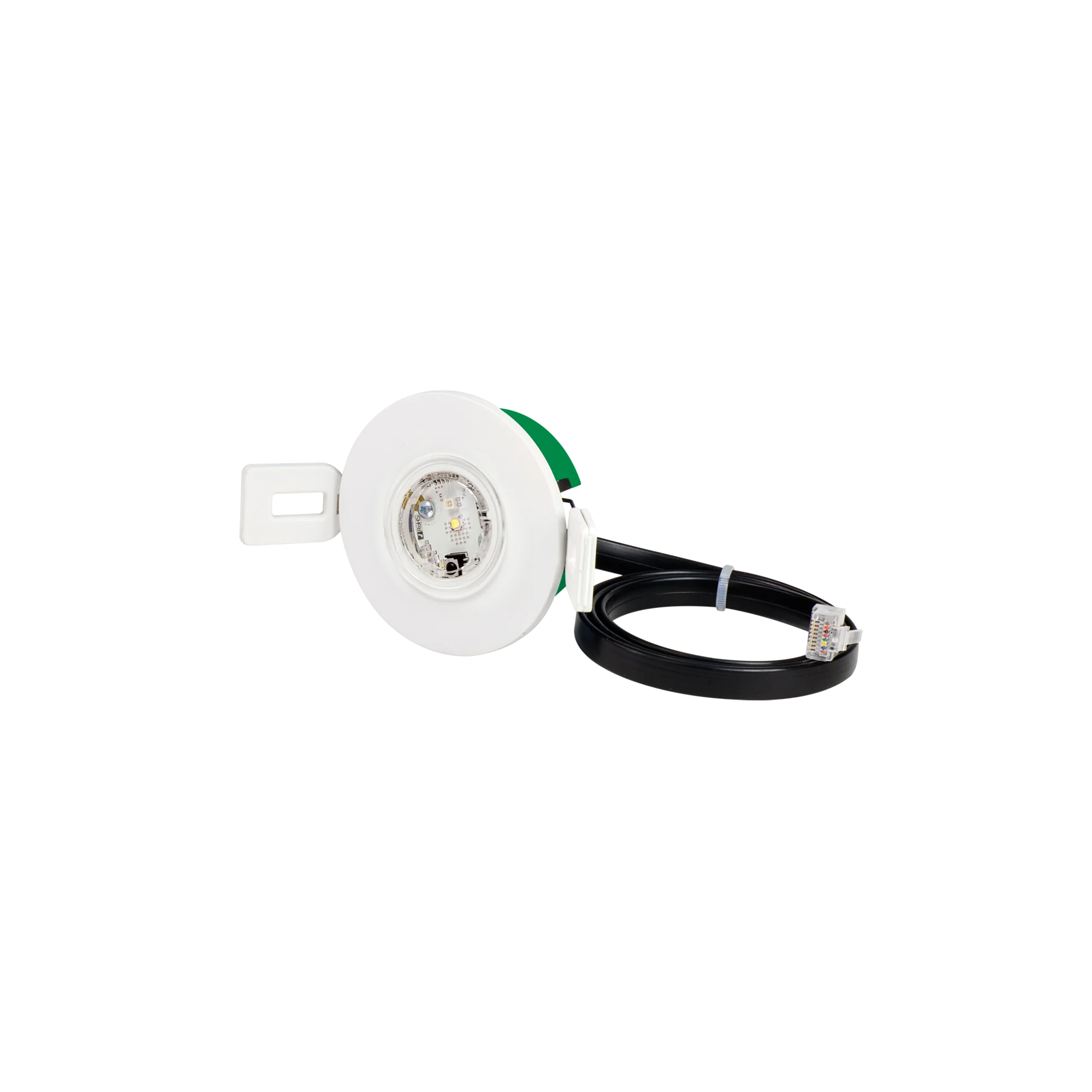

Emergency Lighting

BS 5266-1 recommends areas over 60 m² should be illuminated to a minimum of 0.5 lux. Workshops are often classified as high-risk areas by Risk Assessment, so a higher illumination level is needed to turn off machinery and make equipment safe before evacuation. Specific guidance is given in BS 5266-1 and BS EN 1838.

Find out more